Fuel Analysis

Microbeam has decades of experience investigating the impact of fuel impurities on plant performance, including coal, biomass, petroleum coke and a variety of waste materials. We offer industry-standard ASTM and advanced methods that include scanning electron microscopy and x-ray microanalysis and chemical fractionation to measure the abundance and form of fuel impurities.

Standard Method Analysis

ASTM standard analyses include proximate, ultimate, heating value, ash composition and ash fusion analysis. Proximate analysis provides the moisture, volatile matter and fixed carbon content. Ultimate analysis determines the carbon, hydrogen, nitrogen, oxygen, sulfur, and ash content. Ash composition, or mineral ash, analysis examines the remaining elements in ash. Ash fusion is used to measure the melting behavior of the ash.

Advanced Method Analysis

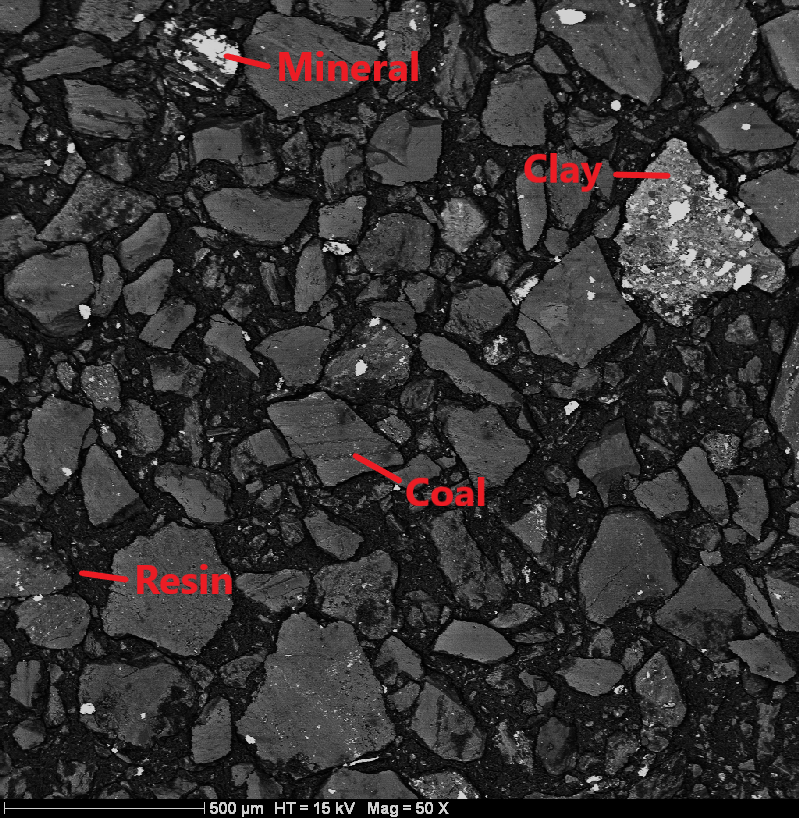

Microbeam’s advanced analyses include scanning electron microscopy methods and chemical fractionation. Microbeam’s SEM methods include providing automated imaging analyses that analyze thousands of particles to provide compositions, mineral abundance and size, and images of the particles. This data can be used to assess mineral behavior during fuel upgrading, gasification, combustion and associations of critical minerals.

Chemical fractionation analysis is used to determine elements that are associated with the organic fraction of the fuel. These analyses help to predict behavior of fuel associated impurity particle behavior in combustion or gasification processes.

Fuel Impurity Analysis

Computer Controlled Scanning Electron Microscopy (CCSEM) analysis helps predict behavior of fuel associated impurity particle behavior in combustion or gasification processes. For selected fuels, such as biomass and lignite coals chemical fractionation analysis is used to determine elements that are associated with the organic fraction of the fuel.

Ash Fusion Testing

MTI uses ash fusion testing to assess when ash transitions from a solid to a liquid state during heating, under both oxidizing and reduction conditions.

Stage 1

Initial

Stage 2

Sample before flow

Stage 3

Sample at flow point

Stage 4

Sample after flow point

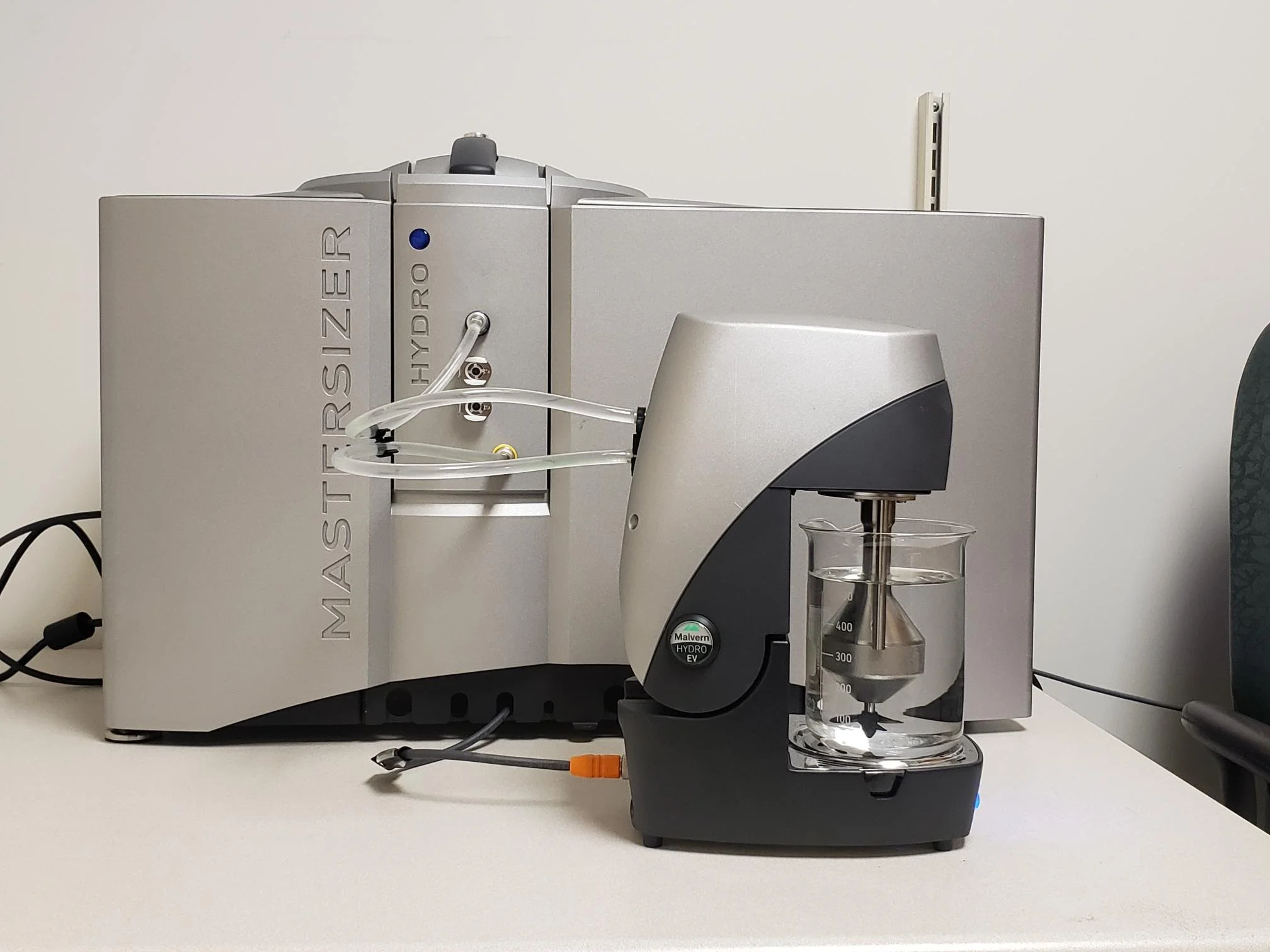

Particle Size

Microbeam’s Malvern Particle Size Analyzer uses laser diffraction to accurately measure small amounts of particles within the ranges of 0.1 µm to 3 mm. This sophisticated tool provides detailed insights into the size distribution of the particles in your sample.

Ash Behavior Indices

Microbeam's unique Indices calculations evaluate a fuel's performance and consider factors such as particle formation and surface effects.

Let’s work together

Interested in learning more? Contact us to see how we can help.