Fuel Tracking & Optimization

Microbeam provides tools to track fuels through a feedstock handling system and manage changes in fuel properties in real-time, from the point of delivery to the burners and control sorting and blending operations to fine-tune fuel properties and reduce disruptions. Microbeam enables you to use multiple online sensors, providing continuous feedback for more control and certainty. Quickly evaluate crucial parameters impacting plant performance. These features facilitate fuel blending options and empower operators to project future fuel quality to the burners.

Fuel Tracking can be used as a standalone tool, but it also provides the backbone for Microbeam’s Plant Performance Optimization tools that enable prediction and control of plant performance based on real-time fuel properties.

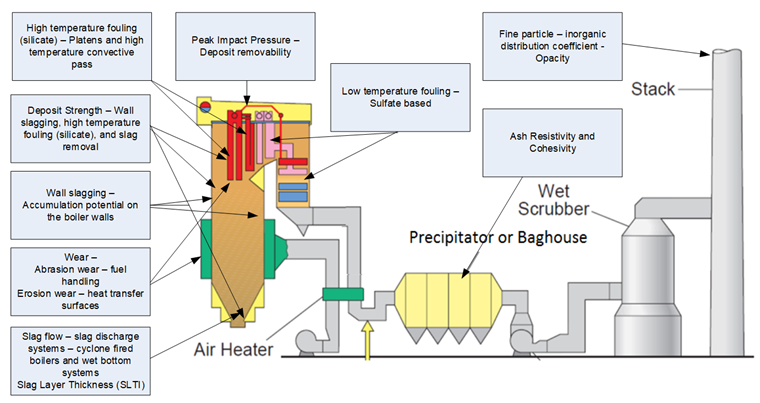

Microbeam’s Ash Behavior Indices

Microbeam's unique fireside indices predicts the impact of fuel properties on energy conversion system performance. In conjunction with fuel tracking, indices can be used to estimate fuel properties and optimize fuel ratios.

Let’s work together

Interested in learning more? Contact us to see how we can help.