Fuel & Plant Management

Microbeam is fully equipped to help plants understand the quality of their incoming fuel and its impacts on plant performance. We help clients process performance issues and suggest operational changes that can be made to produce energy more efficiently. MTI accomplishes this through our combined use of laboratory and SEM analytical methods coupled with advanced data analysis. Past investigations have included such methods as statistical analysis, computer modeling, and neural network training.

Optimization Areas

Operation efficiency coupled with fuel management are cornerstones of a well-run power plant.

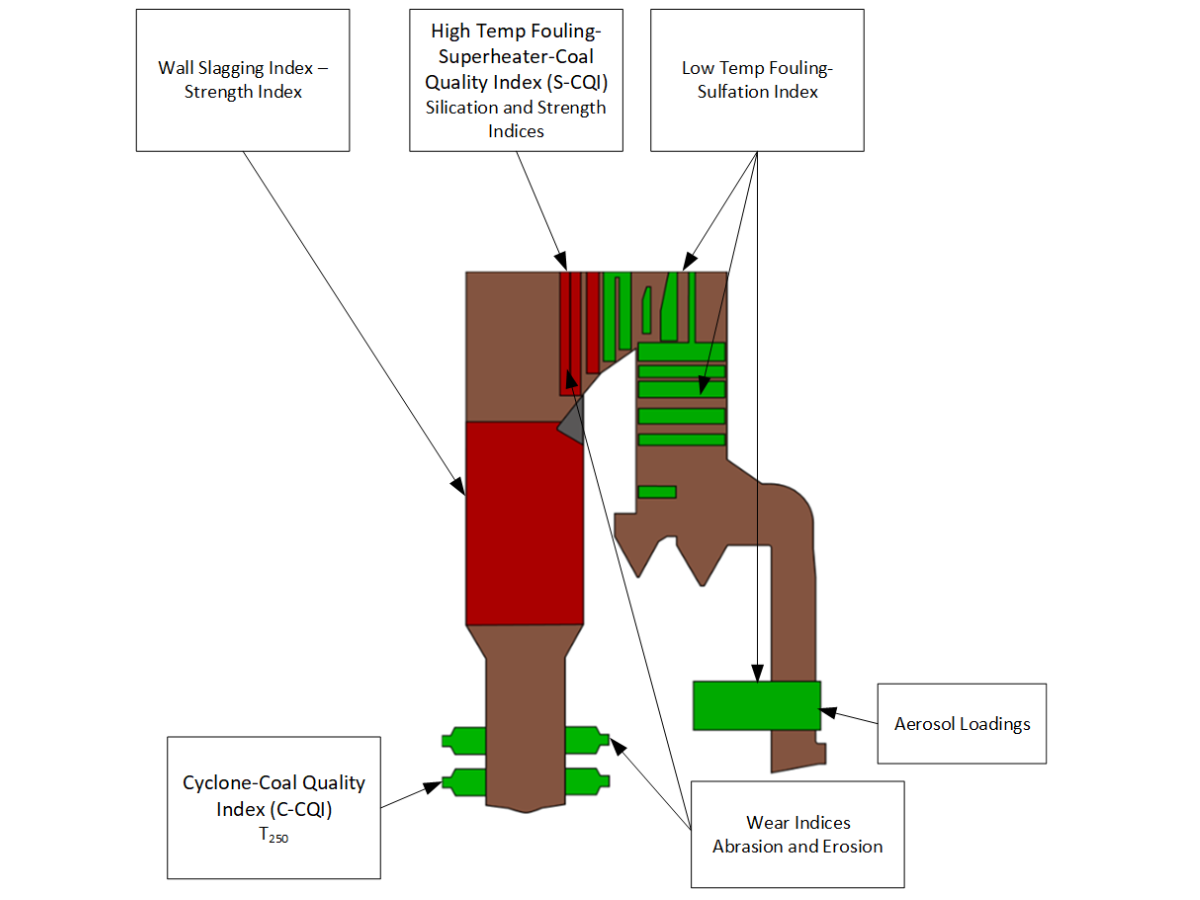

Microbeam uses its decades of fuel quality expertise and plant performance indicators to predict power plant problems and management recurrent issues.

Microbeam Technologies, Inc’s proprietary indices and machine learning algorithms determine fuel quality and relay critical information back to plant operators, engineers, and mine personnel.

-

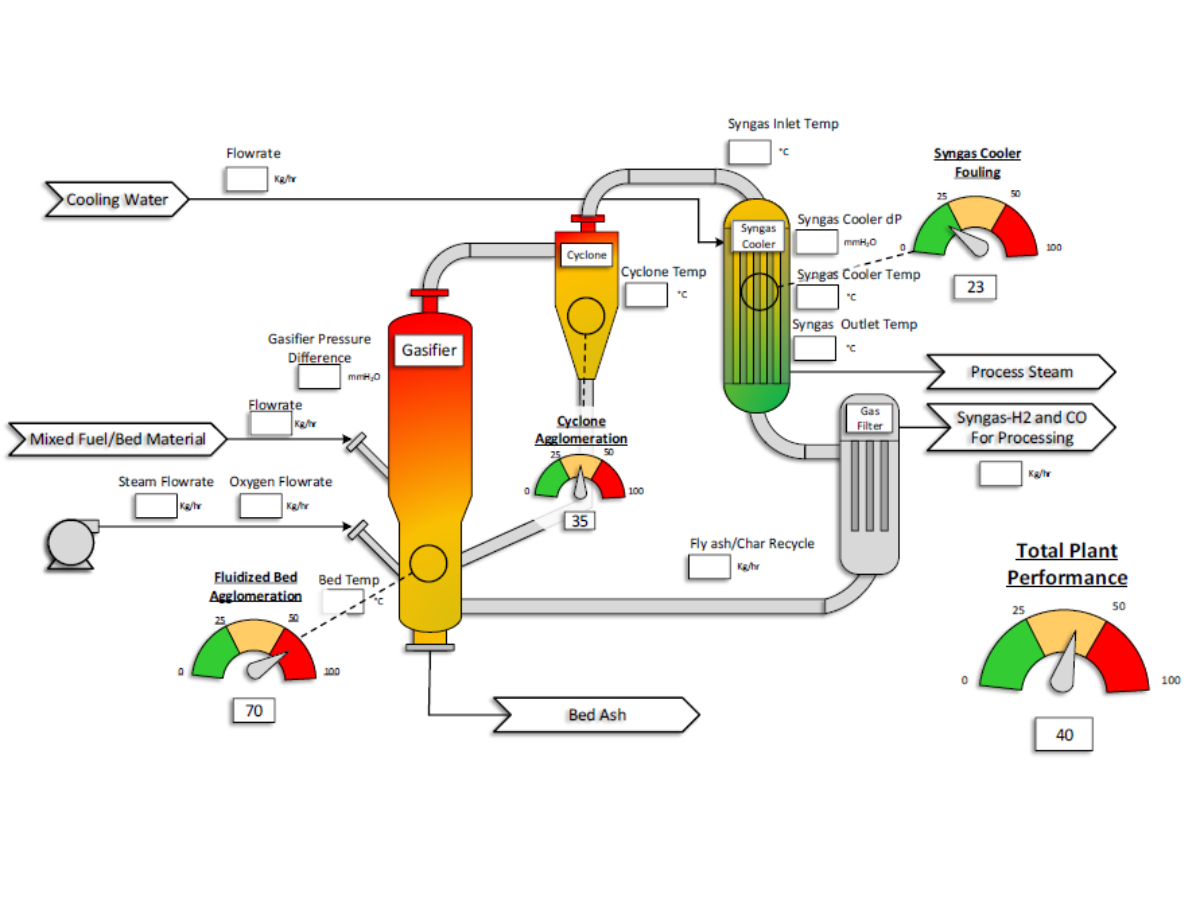

Plant Performance Optimization

Maximize operational efficiency and reliability by predicting plant performance based on real-time estimations of fuel properties and plant state.

-

Fuel Tracking and Optimization

Monitor fuel in real-time from the point of delivery to the burners and control sorting and blending operations to fine-tune fuel properties and reduce disruptions.

Discover what our consulting services can do for your facility. Schedule a consultation with a Microbeam Technologies, Inc. expert today and discuss our fuel and plant management capabilities.

Learn More About Microbeam Technology’s Plant and Fuel Optimization Areas

Case Studies and Infographics

Let’s work together

Interested in learning more? Contact us to see how we can help.