Posts by Category

Understanding Different Types of Fluidized Bed Combustion Systems

Microbeam Technologies, Inc. (MTI) specializes in determining the impact of fuel properties and bed material type on the performance and reliability of fluidized bed combustion (FBC) systems, offering versatile and efficient solutions for burning solid fuels across various industrial processes and power generation applications. Our expertise provides the ability to analyze samples of agglomerates, deposits, fuels, and bed materials to determine the components and operating conditions leading to agglomeration and ash deposition. Based on this information, MTI determines the bonding materials and operating conditions that caused the problem and identifies measures to mitigate agglomerate and deposit formation.

Assessment of Biomass Fuel Blending on Power Plant Performance

Microbeam Technologies, Inc (MTI) offers advanced analytical tools and performance indices designed to understand how ash-related properties affect fuel performance in energy systems. These tools are particularly valuable for evaluating the performance of various coal-biomass fuel blends, helping utilities optimize fuel choices and improve boiler efficiency.

Evaluation of Cenospheres in Fly Ash

Microbeam Technologies, Inc. (MTI) has developed a predictive tool to assess cenosphere formation in different coal fly ash size fractions. This tool is based on the mineral composition, type, and abundance in the coal feedstock and the temperature profile within the boiler, providing a valuable tool for identifying coal feedstocks with high potential for cenosphere formation.

Fluidized-Bed Combustion: Case Study Evaluating Coal Blend Performance

Microbeam Technologies, Inc (MTI) has developed a proprietary experimental test procedure and a set of performance indices to assess the impact of ash-related properties on agglomeration and ash behavior in a fluidized-bed combustion system. These tools offer a predictive capability for assessing the effects of blending different coal feedstocks on ash behavior, helping to optimize system performance.

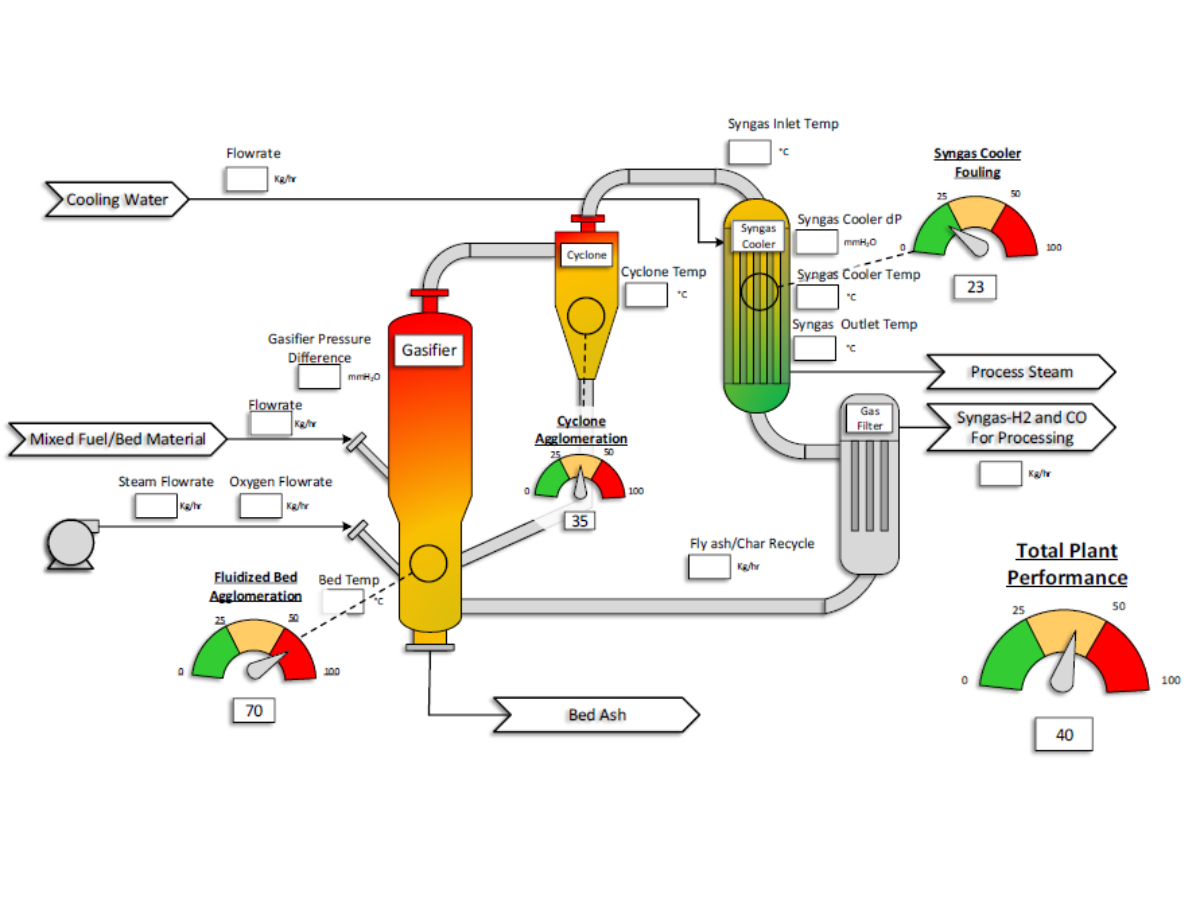

Maximizing Gasification Efficiency and Reliability using Novagen™

Microbeam Technologies, Inc. (MTI) developed a software platform called Novagen™ to manage feedstock properties and optimize operations in gasification systems. Next-generation gasifiers are faced with high-variability challenging feedstocks that threaten to decrease efficiency and force outages. Novagen™ enables dynamic blending of challenging waste feedstocks to maximize efficiency while minimizing downtime.

Assessment of Critical Minerals including Rare Earth Elements in Coal

Microbeam Technologies, Inc (MTI) has developed analytical and modeling tools to determine the abundance and associations of rare earth elements (REE) and selected critical minerals (CM) in coal. These tools are particularly useful in helping clients to identify coal feedstocks with high levels of REE-CM.

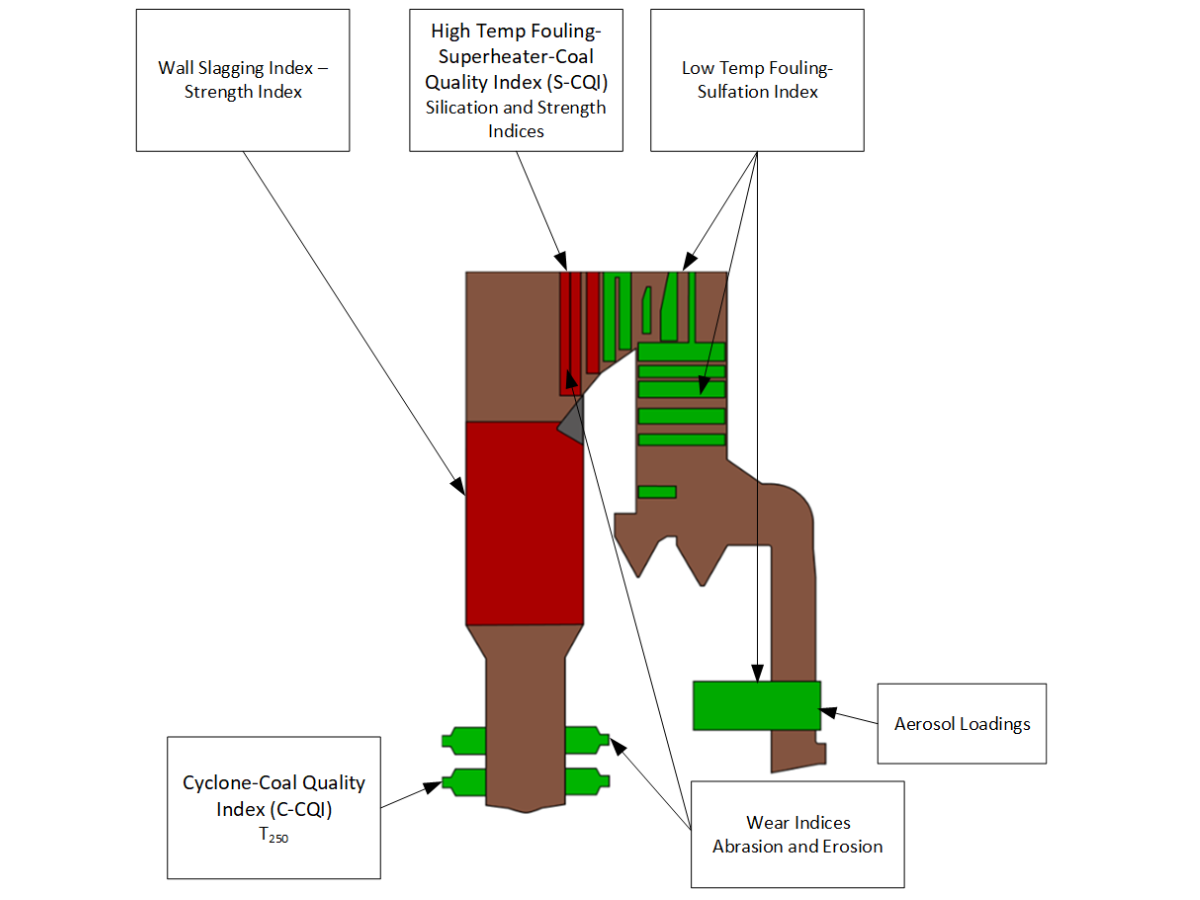

Assessment of the Fireside Performance of Various Coals

Microbeam Technologies, Inc. (MTI) specializes in evaluating the impacts of fuel properties on the fireside performance of various types of coals and biomass fuels. Our unique expertise has helped guide numerous clients worldwide to evaluate and optimize their fuels. This expertise extends to various types of power plants from small to large-scale systems. MTI’s analytical methods and proprietary performance indices are tailored to determine and predict the impact of ash-related materials on coal-fired plant fireside performance. Our vast fuel expertise includes coals of all ranks, energy crops, and various types of biomass and waste materials.

PC-Fired System: Evaluating Coal Blend Performance

Microbeam Technologies, Inc. (MTI) offers specialized tools and performance indices designed to help understand how ash-related properties affect fuel performance in pulverized-coal (PC)-fired systems. These tools are particularly useful for assessing the impact of blending different coal feedstocks on plant operations and ash properties.

Cyclone-Fired System: Optimizing Coal Blend Performance

Microbeam Technologies, Inc (MTI) offers advanced analytical tools and performance indices designed to assess how different coals and blends of coal impact the efficiency and reliability of cyclone-fired combustion systems. These tools help identify how changes in fuel composition, particularly through blending various coals, affect system performance. Microbeam Technologies, Inc (MTI) has developed analytical methods and proprietary performance indices tailored to predict the impact of ash-related properties on fuel performance for a cyclone-fired system. These tools can be used to determine the effects of changing the fuel composition when blending two or more coal feedstocks.

Energy System Performance Manager

Microbeam Technologies, Inc. (MTI) developed the Energy Systems Performance Manager (ESPM) to monitor, manage, and optimize operations in various types of power plants and fuel handling systems. The ESPM tracks fuel properties and composition information from on-line sensors fuel handling system to the burner. The system is designed to sort and blend fuel based on the plant’s optimum performance parameters and feedstock available. The ESPM also monitors current performance and can be used to forecast performance based on current fuel inventory.