Understanding Different Types of Fluidized Bed Combustion Systems

Key Applications

Design and implementation of a fluidized bed combustion system

Retrofitting fluidized bed combustion systems to conventional boilers

Improving combustion efficiency and reliability

Introduction

Microbeam Technologies, Inc. (MTI) specializes in determining the impact of fuel properties and bed material type on the performance and reliability of fluidized bed combustion (FBC) systems, offering versatile and efficient solutions for burning solid fuels across various industrial processes and power generation applications. Our expertise provides the ability to analyze samples of agglomerates, deposits, fuels, and bed materials to determine the components and operating conditions leading to agglomeration and ash deposition. Based on this information, MTI determines the bonding materials and operating conditions that caused the problem and identifies measures to mitigate agglomerate and deposit formation.

Background

A FBC system is a combustion technology wherein solid fuels are burned in a bed of suspended particles by blowing air through it, allowing for efficient mixing. FBC systems have high fuel flexibility and can operate with different types of coal, biomass, or even low-grade fuels such as petroleum coke or “petcoke”. FBCs also offer enhanced temperature control, efficient heat transfer, and reduced emissions.

FBC systems can be divided into three main types depending on the velocity of the air being blown through the fluid bed (Figure 1).

Bubbling fluidized bed (conventional)

Circulating fluidized bed

Transport reactor

MTI has completed numerous projects on agglomeration and ash deposition in fluidized bed combustion. These projects have provided MTI with a detailed understanding of the transformations of fuel impurities during combustion and gas cooling; bed particle coating and bonding processes; mechanisms of ash accumulation on boiler walls, cyclones, and convective surfaces; and the impacts of bed material properties and additives. This knowledge is crucial for selecting fuels, bed materials, and possible additive combinations that minimize ash related issues in FBC systems.

Figure 1. Diagram depicting three main types of FBC systems.

Bubbling Fluidized Bed

Bubbling fluidized beds are considered the original fluid bed combustion boiler. They use low-velocity combustion air to move fuel through a bed of inert material. The bubbling action of the air causes the fuel particles to behave like a boiling liquid, which promotes even combustion. In a bubbling bed, relatively high solids densities are maintained in the bed and only a small fraction are entrained from the bed. Bed agglomeration and fouling of heat transfer surfaces can present significant challenges to operational efficiency and reliability.

In a previous project involving a bubbling FBC system, MTI utilized scanning electron microscopic (SEM) imaging and x-ray microanalysis to analyze deposit and agglomerate cross sections. Ash deposits from downstream heat exchangers were found to consist mainly of highly bonded sulfate materials derived from fine ash materials (Figure 2). Figure 3 shows a highly bonded agglomerate, wherein sand bed particles are coated with alkali sulfate and silicate bonding materials.

Figure 2. (Left) Superheater deposit; Figure 3. (Right) Highly bonded agglomerate.

Circulating Fluidized Bed

Circulating fluidized bed (CFB) systems use a recirculating loop to increase combustion efficiency and reduce pollutant emissions. During this process, fine particles elutriated out of the furnace are collected and circulated back into the furnace (solids reycling is around 50-100 kg/kg of fuel burned). SEM cross-sections of deposits and agglomerates are shown in Figures 4-6 from a CFB firing a combination of petcoke and other fuels. The cyclone deposit in Figure 4 shows layering of a highly sulfated matrix containing alkali and alkaline earth elements. Figure 5 shows very small (<10µm) bonded particles contributing to the formation of bonded deposits on the convective pass heat transfer surface downstream of the cyclone. Figure 6 shows a sulfate-coated sand particle next to sulfate-bonded particles derived from the limestone bed material.

Figure 4. (Left) Cyclone deposit; Figure 5. (Middle) Heat transfer deposit; Figure 6. (Right) Bed agglomerate.

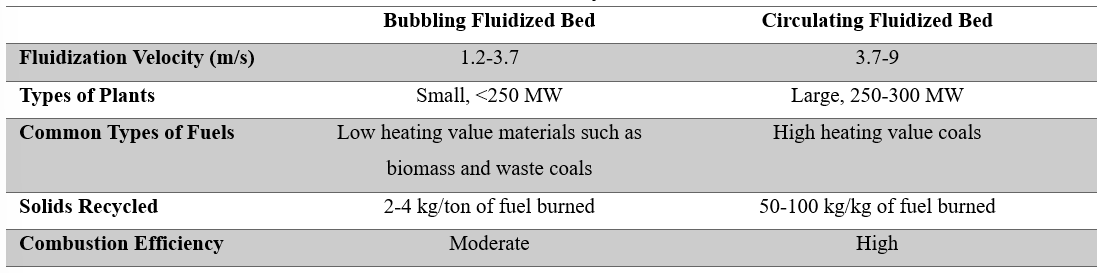

Key comparisons between bubbling and circulating FBC systems are summarized in Table 1. Due to the high combustion efficiency of CFB systems, they are more commonly utilized in large-scale gasification systems. While high heating value coals are common for CFBs, biomass and waste coals are often utilized in bubbling FBC systems. CFBs are also characterized by higher fluidization velocities and increased efficiency of solids recycling.

Table 1. Characteristics of fluidized bed combustion systems.

Transport Reactors

Transport reactor systems are commonly used in power generation, refining, chemical production, and environmental control. In transport reactors, the bed vessel is operated at pressures up to 16 ata (16 mg/cm2). Transport reactors use the same exit temperatures as the other types of fluid-bed reactors but with shorter solids residence times, ranging from 5-30 seconds.

Summary

FBC systems, including bubbling, circulating, and transport reactors, provide flexibility in fuel types and enhanced performance through improved temperature control and emissions. Whether implementing new systems, retrofitting existing boilers, or enhancing operational reliability, MTI is commited to providing innovative and customized solutions to minimize the impacts of ash materials for all FBC applications.