Assessment of Biomass Fuel Blending on Power Plant Performance

Introduction

Microbeam Technologies, Inc (MTI) offers advanced analytical tools and performance indices designed to understand how ash-related properties affect fuel performance in energy systems. These tools are particularly valuable for evaluating the performance of various coal-biomass fuel blends, helping utilities optimize fuel choices and improve boiler efficiency.

Background

The demand for biomass-based fuels is increasing as power plants aim to transition toward carbon-neutral and carbon-negative operations. Co-firing biomass with coal significantly reduces greenhouse gas emissions. However, using biomass in coal-fired boilers has the potential to introduce operational challenges, including:

Corrosion of heat transfer surfaces

Fouling and slagging at both high and low temperatures

Increased flue gas temperatures

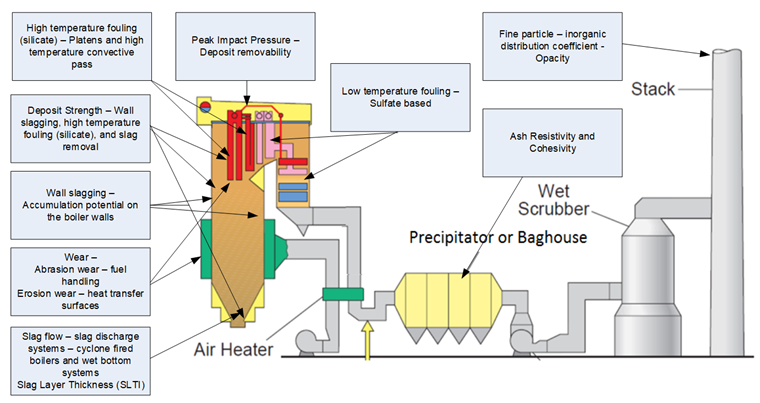

MTI has developed advanced performance indices that relate fuel properties to ash behavior in a biomass/coal-fired utility boiler (see Figure 1). These indices can be used to predict how incorporation of biomass into fuels will impact boiler performance.

Figure 1. Biomass/Coal-Fired Utility Boiler Performance and Modeling Approach.

Case Study: Evaluating Coal-Biomass Blends

This case study focuses on blending a low ash biomass with high levels of alkali and alkaline earth elements with a high fouling lignite coal. The client sought MTI's expertise to evaluate how different coal-biomass blends would impact combustion system performance.

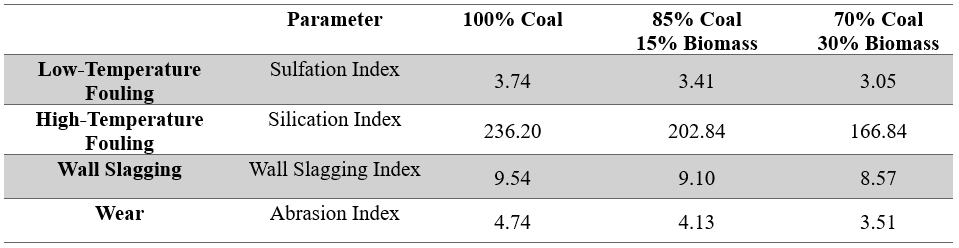

Performance predictions developed by MTI suggest that increasing the proportion of biomass in the coal-biomass blends improves boiler performance (Table 1).

Table 1. Selected performance indices for coal-biomass blends.

Key Findings:

Sulfation Index: This index estimates the risk of low-temperature fouling deposits and is influenced by alkali and alkaline earth elements. Blends with more biomass exhibited a decreased Sulfation Index, indicating lower risk of low-temperature fouling.

Silication Index: This index predicts the tendency of forming high-temperature fouling deposits. Higher proportions of biomass in the blend were associated with a lower Silication Index, indicating reduced fouling risk.

Wall Slagging Index: A decrease in this index suggests that increasing the proportion of biomass in the blend reduces the likelihood of high-temperature deposits forming on the radiant walls of the boiler. This index is related to mineral size, calcium association, and slag viscosity.

Abrasion Index: A decrease in this index indicates that the potential for wear of fuel preparation and handling equipment is lower for blends with higher proportions of biomass. This index is related to the presence of hard minerals such as quartz and pyrite.

Summary

MTI provides cutting-edge analytical tools and predictive indices to evaluate the impact of biomass blending on the performance of coal-fired utility boilers. By leveraging these tools, plant operators can make informed decisions to optimize fuel blends, move toward carbon-neutral operations, and maintain plant efficiency.