PC-Fired System: Evaluating Coal Blend Performance

Introduction

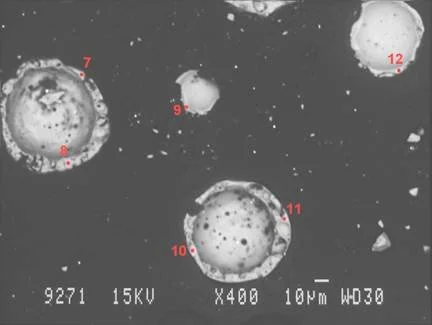

Figure 1. Backscattered electron image showing coal fly ash cenospheres.

Microbeam Technologies, Inc. (MTI) offers specialized tools and performance indices designed to help understand how ash-related properties affect fuel performance in pulverized-coal (PC)-fired systems. These tools are particularly useful for assessing the impact of blending different coal feedstocks on plant operations and ash properties.

Background

Pulverized Coal (PC) boilers are commonly used in U.S. power plants. In these systems, coal is ground into a fine powder, mixed with air, and burned in the firebox to generate thermal energy. Biomass and other materials can also be added to the coal mix. The combustion process produces bottom ash and fly ash, which are removed from the system. Ash also produces fireside deposits on heat transfer surfaces decreasing reliability and increasing maintenance costs.

Key concerns in PC-fired systems related to fuel properties include:

Wear on fuel handling systems and heat transfer surfaces

Wall slagging and fouling at both high and low temperatures

Ash utilization, particularly the salability of fly ash for concrete production as well as the formation of value added cenospheres

Emissions of sulfur and particulate matter

Fly ash, which can form cenospheres during combustion, is valuable as a concrete additive (see Figure 1). The behavior of ash significantly affects plant performance, as detailed in Figure 2. MTI’s performance indices help predict how changes in feedstock composition, such as blending different coals, will impact these areas.

Figure 2. PC-Fired System Performance and Modeling Approach.

Case Study: Evaluating Coal Blend Performance in a PC-Fired System

This case study focuses on a PC boiler with two units, each with a generating capacity of 550 MW, totaling 1.1 GW. MTI collaborated with the University of North Dakota to examine how blending different coal feedstocks affects performance. Upon comparing key performance predictions, increasing the amount of Coal #2 in the blend improved performance (Table 1).

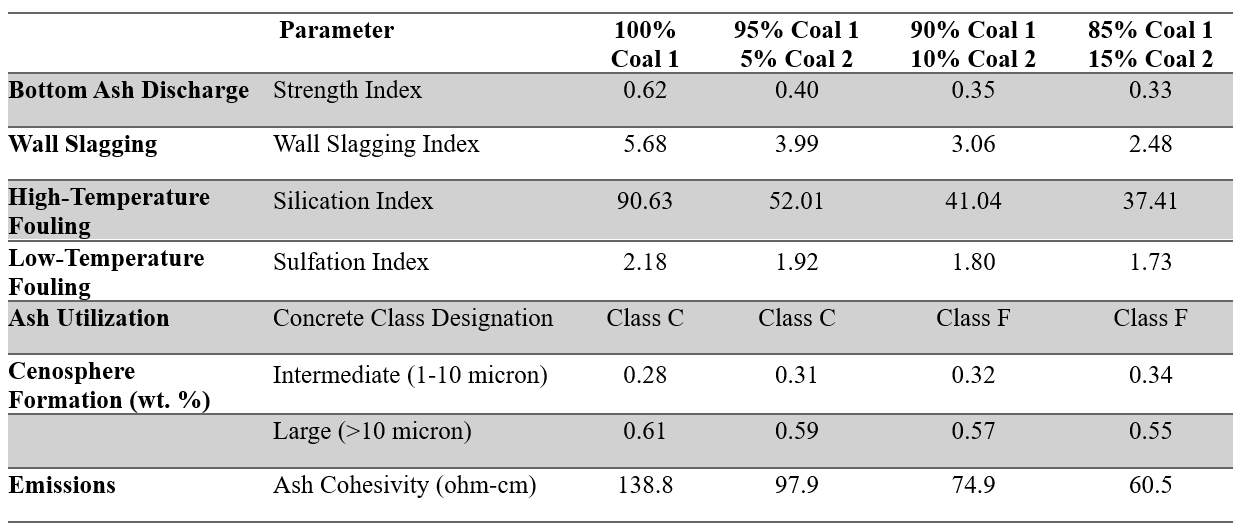

Table 1. Summary of key results from coal blend analysis and modeling.

Key findings are summarized below:

Strength Index: Higher proportions of Coal #2 in the blend were associated with a lower Strength Index, indicating reduced deposit strength.

Wall Slagging Index: A decrease in this index suggests that increasing the proportion of Coal #2 in the blend reduces the likelihood of high-temperature deposits on the boiler’s radiant walls. This index considers mineral size, calcium association, and the viscosity of the liquid slag.

Silication Index: This index predicts the tendency for high-temperature fouling deposits. Higher proportions of Coal #2 in the blend were associated with a lower Silication Index, indicating reduced fouling risk.

Sulfation Index: This index measures the potential for low-temperature fouling deposits in the convective pass. As Coal #2 proportion increased, the Sulfation Index decreased, meaning there’s less chance of low-temperature deposits.

Concrete Class: Increasing Coal #2 to 10% improved the concrete’s quality from Class C to Class F, due to a reduction in calcium content.

Cenosphere Formation: Only slight differences in cenosphere formation were predicted as the proportion of Coal #2 in the blends was increased.

Cohesivity Index: This index assesses the fly ash’s ability to bond at low temperatures, affecting its handling. Higher amounts of Coal #2 resulted in lower cohesivity, making the fly ash easier to manage.

Summary

MTI’s analytical methods and performance indices provide valuable insights into how blending different coal feedstocks impacts combustion performance in PC-fired systems. By leveraging these tools, you can optimize fuel blends to enhance efficiency, reduce operational issues, and improve overall plant performance.