Cyclone-Fired System: Optimizing Coal Blend Performance

Introduction

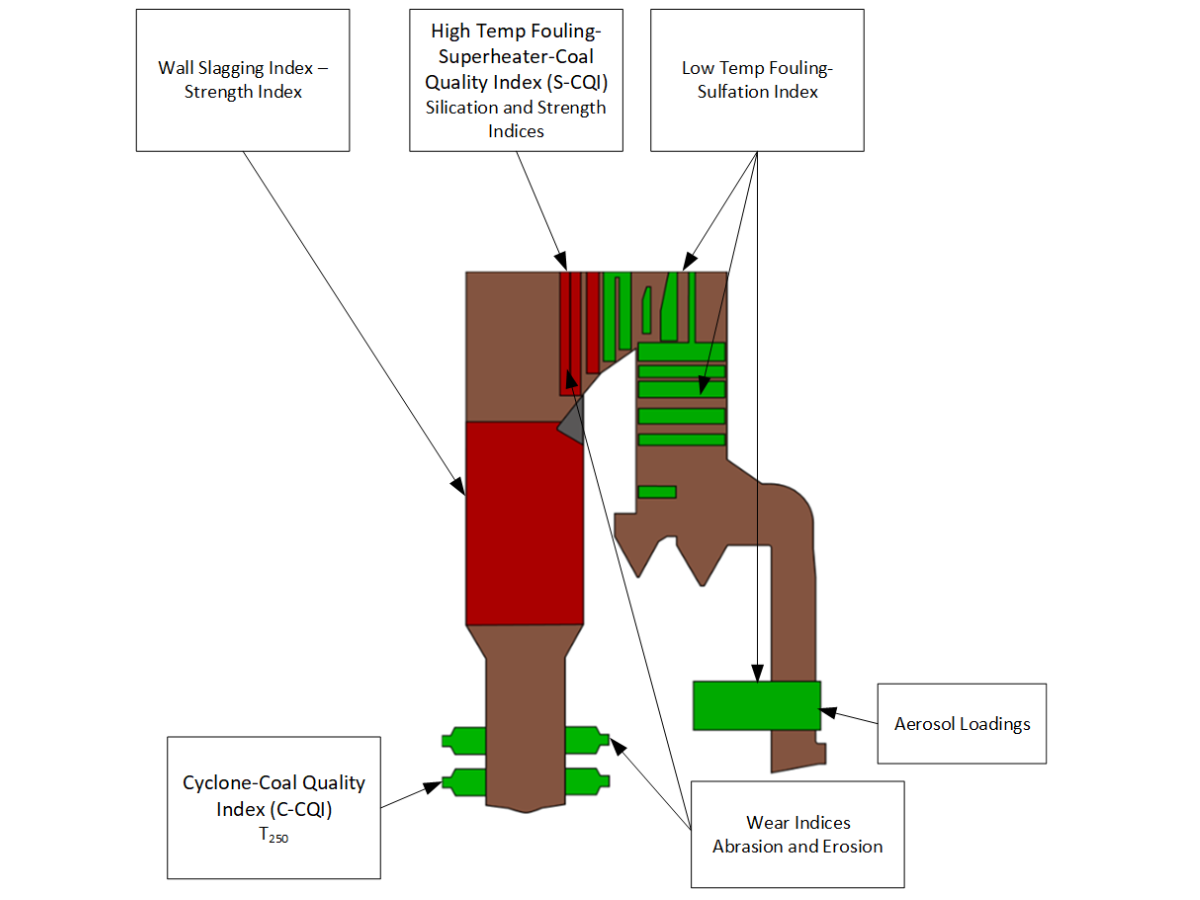

Microbeam Technologies, Inc (MTI) offers advanced analytical tools and performance indices designed to assess how different coals and blends of coal impact the efficiency and reliability of cyclone-fired combustion systems. These tools help identify how changes in fuel composition, particularly through blending various coals, affect system performance. Microbeam Technologies, Inc (MTI) has developed analytical methods and proprietary performance indices tailored to predict the impact of ash-related properties on fuel performance for a cyclone-fired system. These tools can be used to determine the effects of changing the fuel composition when blending two or more coal feedstocks.

Background

Cyclone-fired systems use cyclone burners, which are barrel-shaped and operate by swirling fuel in a cyclone motion. Secondary air introduced tangentially at the burner’s top helps sustain the combustion process. In these systems, a significant amount of fuel ash is captured as molten slag and removed from the furnace’s bottom and the remaining ash is transported through combustion system to form fly ash.

Fuel properties in cyclone-fired systems can significantly impact performance, influencing factors such as:

Wear and tear on fuel handling systems and heat transfer surfaces

Slag flow and wall slagging

Fouling at both high and low temperatures

Ash utilization

Emissions of sulfur and particulates

MTI has developed indices to predict how different coal blends will affect these factors and overall cyclone performance.

Figure 1. Cyclone-Fired System Performance and Modeling Approach.

Case Study: Coal Blend Impact on Cyclone-Fired System Performance

This case study examines a cyclone boiler with a capacity of 465 megawatts, using 354 tons per hour of coal and generating approximately 3 million pounds of steam per hour, with a design furnace exit gas temperature of 1950 ºF.

Table 1. Summary of coal blend analysis and modeling results.

Key findings from the analysis are summarized below:

T250 Temperature: This index indicates the temperature at which slag viscosity reaches 250 poise. Blends with more Coal #2 require higher temperatures for slag to flow, as shown by increased T250 values.

Cyclone Coal Quality Index (C-CQI): This index measures the likelihood of cyclone slagging issues based on mineral composition and size. A higher C-CQI suggests that increasing the amount of Coal #2 in the blend raises the risk of slagging or poor slag flow.

Wall Slagging Index: This index predicts the likelihood of forming deposits on the boiler’s radiant walls. This index decreased for blends with more Coal #2, reducing the risk of deposit formation.

Superheater Coal Quality Index (S-CQI): This index predicts the potential for high-temperature fouling in the boiler’s convective pass region. Higher amounts of Coal #2 are associated with increased fouling.

Sulfation Index: This index estimates the risk of low-temperature fouling deposits, influenced by alkali and alkaline earth elements. Blends with more Coal #2 show a decreased Sulfation Index, indicating lower risk of low-temperature fouling.

Aerosol Loadings: Predicted by MTI’s Ash Generator model, increased aerosol loadings indicate that higher proportions of Coal #2 lead to more fine particle formation, which can contribute to ash deposition problems.

Summary

MTI provides a suite of analytical tools and performance indices to help optimize the use of coal blends in cyclone-fired combustion systems. By understanding how different coal mixtures impact performance and potential issues, plant operators can make informed decisions to improve efficiency and manage problems effectively.