Fuel Analysis

Microbeam has decades of experience investigating the impact of fuel impurities on plant performance.

Fuels investigated include but not limited to coal (all ranks), biomass (wet, dry, or torrefied), petroleum coke, and a variety of waste materials.

Microbeam routinely receives and ships client samples domestic and internationally. Quotes are customizable to a client’s unique needs.

Samples often arrive at our facilities in a various stage of drying or sample processing. Microbeam is equipped to accommodate most samples that require additional prep such as drying or grinding to the correct sample size for standard laboratory testing. For specific questions related to sample prep please contact For more information specifically about our grinding and splitting capabilities please refer to our materials preparation page.

Coal

ex. Lignite

Petcoke

ex. Wet Slurry

Biomass

ex. Wood Chips

Biomass

ex. Elephant Grass

Waste Material

ex. Waste Plastics

Waste Material

ex. Waste Tires

Laboratory Analysis of Fuel

Microbeam’s laboratory analyses of fuels includes ASTM standard methods. Fuel analysis commonly requested can include but is not limited to proximate, ultimate, ash composition, sulfur forms. The details of each analysis are provided below.

Proximate Analysis

Proximate analysis is performed using the ASTM D 121 standard methodology. This method is also referred to as “prox.” During proximate analysis, coal is heated under set conditions.

Proximate results delivered include:

Total Moisture - reported on a percent as received basis

Volatile Matter - reported on a percent as received basis and percent dry basis

Fixed Carbon - reported on a percent as received basis and percent dry basis

Ash - reported on a percent as received basis and percent dry basis

Heating Value - reported as BTU/lb

Volatile matter is the vapor given off during the pyrolysis process. Fixed carbon is the nonvolatile matter in a sample. Fixed carbon is calculated by subtracting the sum of the moisture, ash, and volatile matter percents from 100. Ash is the matter remaining after combustion. Total moisture is moisture in and on the sample.

“Short prox” is favored in the field and provides most of the proximate results excluding Fixed carbon determination.

Ultimate Analysis

Ultimate analysis is performed using the ASTM D 3176 standard methodology. Ultimate results represent the elemental composition of the organic material in a sample plus the organic material in the water contained in said sample. Note, corrections are made for the carbon, hydrogen, and sulfur in a sample. The organic material is reported in terms of carbon, hydrogen, nitrogen, sulfur, and oxygen on a percent as received basis and percent dry basis.

Ultimate results delivered include:

Carbon - reported on a percent as received basis and percent dry basis

Hydrogen - reported on a percent as received basis and percent dry basis

Nitrogen - reported on a percent as received basis and percent dry basis

Total Sulfur - reported on a percent as received basis and percent dry basis

Oxygen by Difference - reported on a percent as received basis and percent dry basis

Ash Composition (Mineral Analysis of Ash)

Ash composition analysis is used to determine the composition of the major and minor mineral constituents in ash residue post-combustion.

ASTM D 3682 is the standard methodology used to determine the major and minor elements in a sample via Atomic Absorption Spectrometry (AAS). Trace Elements are determined using ASTM D 3683 methods and AAS. Ash constituent results are reported as weight percents in ash on a dry basis.

Delivered Mineral Analysis of Ash results include:

Silicon Dioxide - reported on a wt.% dry basis in ash

Aluminum Oxide - reported on a wt.% dry basis in ash

Titanium Dioxide - reported on a wt.% dry basis in ash

Iron Oxide - reported on a wt.% dry basis in ash

Calcium Oxide - reported on a wt.% dry basis in ash

Magnesium Oxide - reported on a wt.% dry basis in ash

Potassium Oxide - reported on a wt.% dry basis in ash

Sodium Oxide - reported on a wt.% dry basis in ash

Sulfur Trioxide - reported on a wt.% dry basis in ash

Phosphorus Pentoxide - reported on a wt.% dry basis in ash

Strontium Oxide - reported on a wt.% dry basis in ash

Barium Oxide - reported on a wt.% dry basis in ash

Manganese Dioxide - reported on a wt.% dry basis in ash

X-Ray Fluorescence Spectrometry (XRF)

X-Ray Fluorescence Spectrometry (XRF) is another analytical method used to quickly determine the major and minor elements in a sample. MTI’s uses ASTM D 4326 as the standard methodology for this method.

Sulfur Forms (Forms of Sulfur)

Forms of Sulfur for a sample is determined using the ASTM D 2492 standard methodology. Sulfate and pyritic sulfur are directly determined. Organic sulfur is calculated as the difference between the total sulfur and the sum of the sulfate and pyritic sulfur. For coals, organic sulfur and pyrites are the main forms of sulfur found.

Sulfur forms delivered include:

Organic Sulfur Forms - reported on a percent as received basis and percent dry basis

Pyritic Sulfur Forms - reported on a percent as received basis and percent dry basis

Sulfate Sulfur Forms - reported on a percent as received basis and percent dry basis

Total Sulfur - reported on a percent as received basis and percent dry basis

Halogen Analysis

Halogen analysis involves determination of chlorine (Cl), Bromine (Br), or Fluorine (F) in a sample. This can be of particular interest concerning biomass fuels but is not limited to biomass samples. Results are reported as percent or ppm.

Chemical Fractionation

Chemical fractionation is used to determine elements that are associated with the organic fraction of the fuel. These analyses help to predict behavior of fuel associated impurity particle behavior in combustion or gasification processes.

Loss On Ignition Testing (LOI)

Loss on ignition (LOI) is an analytical method used to measure the organic matter within a sample. Results report the mass lost by the sample after heating to a designated temperature. MTI uses the ASTM D 3174 standard methodology for LOI testing of samples.

Ash Fusion Testing

Ash fusion tests are used to measure the melting behavior of ash. MTI uses ash fusion testing to assess when ash transitions from a solid to a liquid state during heating, under both oxidizing and reduction conditions.

Stage 1

Initial

Stage 2

Sample before flow

Stage 3

Sample at flow point

Stage 4

Sample post flow point

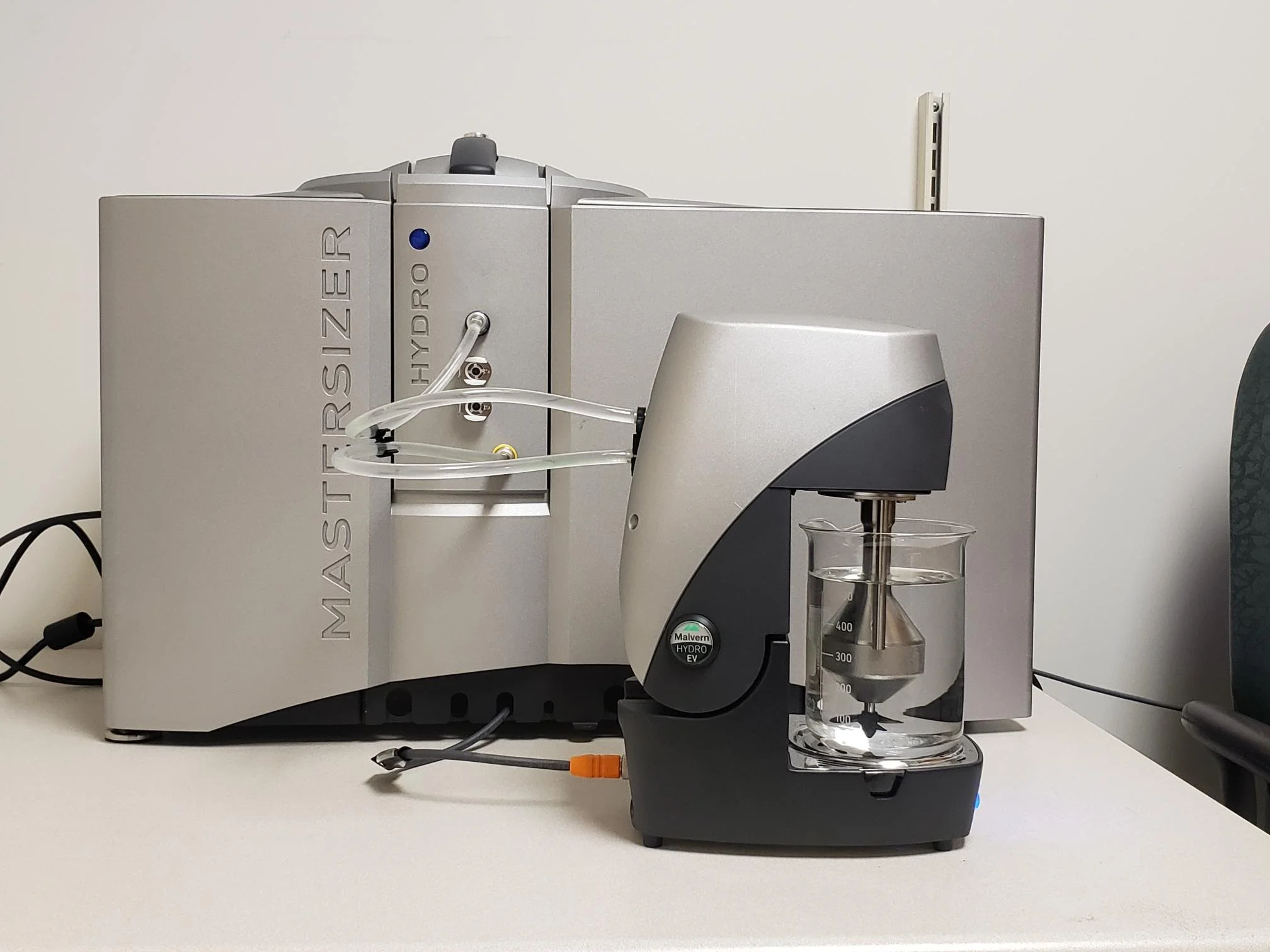

Particle Size Distribution

Microbeam’s Malvern Particle Size Analyzer uses laser diffraction to accurately measure small amounts of particles within the ranges of 0.1 µm to 3 mm. This sophisticated tool provides detailed insights into the size distribution of the particles in your sample.

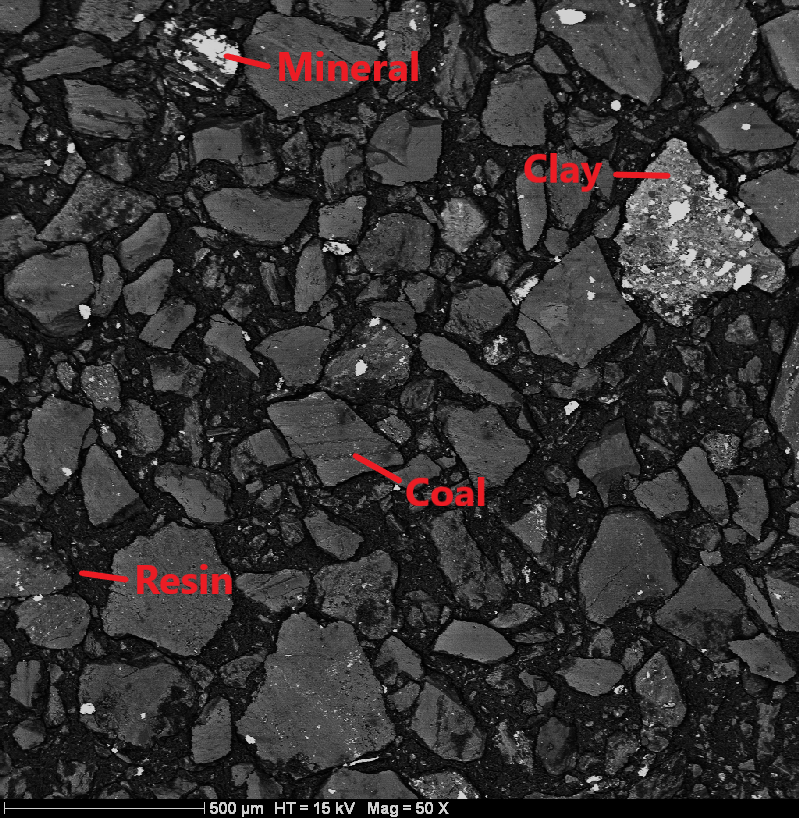

Scanning Electron Microscopy - Fuel Analysis

Microbeam’s SEM methods include providing automated imaging analyses that analyze thousands of particles to provide compositions, mineral abundance and size, and images of the particles. This data can be used to assess mineral behavior during fuel upgrading, gasification, combustion and associations of critical minerals.

Analysis of Fuel Impurities

SEM Computer Controlled Scanning Electron Microscopy (CCSEM) analysis helps predict behavior of fuel associated impurity particle behavior in combustion or gasification processes. For select fuels, such as biomass and lignite coals chemical fractionation laboratory analysis is used to determine elements that are associated with the organic fraction of the fuel.

To learn more about these methods please visit our CCSEM page and/or Chemical Fraction page.

These pages give in-depth descriptions of each method along with a workflow of the process from sample prep to results.

Let’s work together

Interested in learning more? Contact us to see how we can help.