Scanning Electron Microscopy Point Count SEMPC

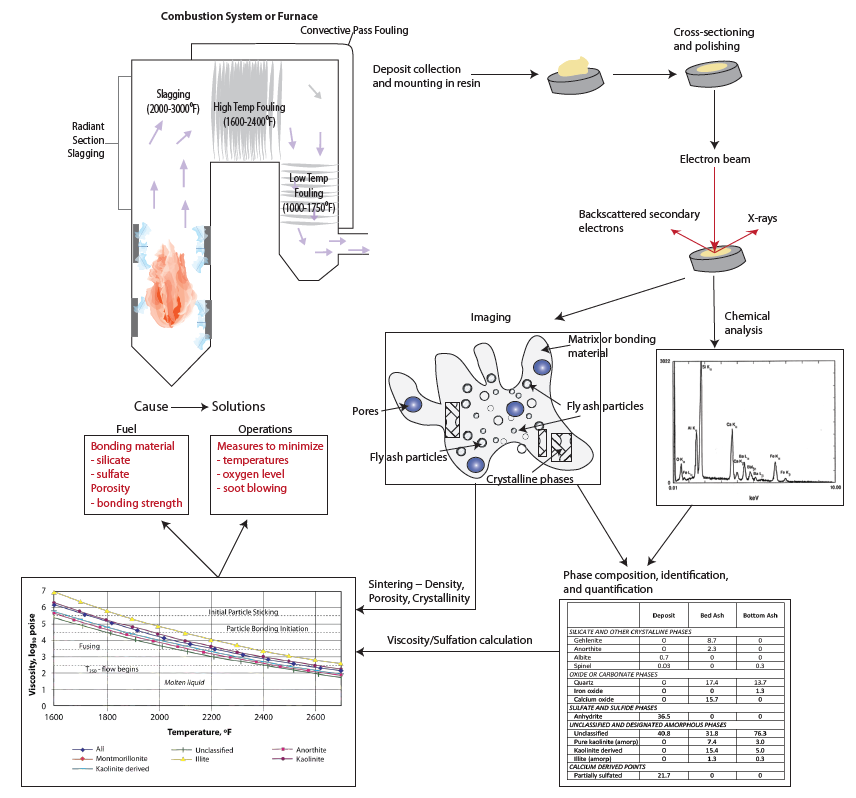

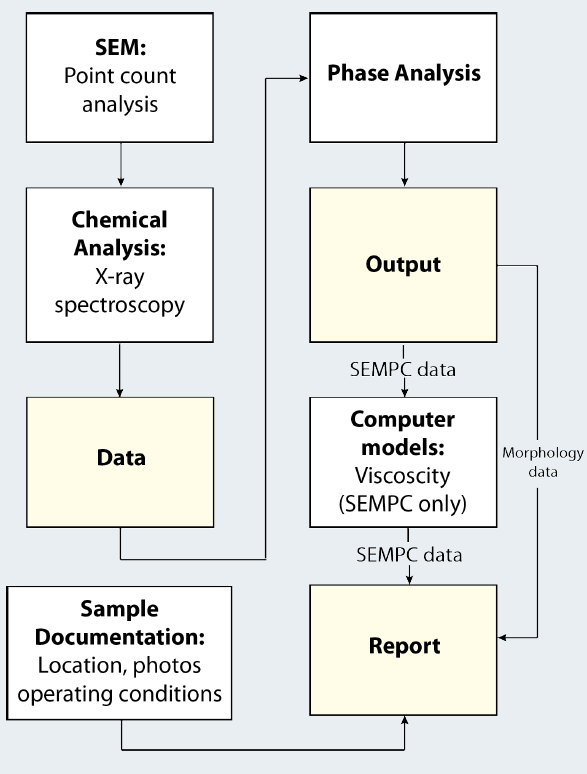

MTI uses scanning electron microscopy point count (SEMPC) to characterize entrained ash and deposits. This technique provides information on the degree of melting and interaction of various deposited ash particles as well as quantitative information on the abundance of phases present. We use this information to identify the material responsible for the deposit. SEMPC can also be used to identify and quantify the amount of melted phases and their viscosities. We examine various regions in deposits and individual entrained ash particles to determine the changes that occurred with operating conditions (temperature and oxygen levels).

Often by combining SEMPC with morphological analysis, MTI can provide a good understanding of a particular deposition problem, which can be used toward determining effective operational adjustments to reduce or eliminate the ash-related problem.

Compare with

SEM Morphological Analysis, which is used to fully characterize materials. An SEM morphology provides information about the physical relationships of the size, crystallinity, and juxtaposition of the phases present.

or Computer-Controlled Scanning Electron Microscopy (CCSEM), which is used to determine the size, composition, abundance, and association of mineral grains in prepared coal, biomass, and petroleum-coke samples. Utilizing this method allows us to assess the behavior of the mineral grains during combustion or gasification.

SEMPC Analysis

SEMPC Method

Let’s work together

Interested in learning more? Contact us to see how we can help.